How should customers choose between long-distance monitoring (e.g., kilometers of cable) and high-precision point sensing (e.g., motor bearings)?

The choice between long-distance monitoring and high-precision point sensing depends on the specific application requirements and the type of data you need to acquire.

For long-distance monitoring (e.g., kilometers of cable in pipelines, tunnels, or power lines), Distributed Fiber Optic Sensing (DFOS) technologies like DTS (Distributed Temperature Sensing), DAS (Distributed Acoustic Sensing), or DSS (Distributed Strain Sensing, often based on Brillouin or Rayleigh scattering) are typically employed. These systems use the fiber optic cable itself as the sensing element, providing a continuous profile of temperature, strain, or acoustic events along its entire length. This approach is ideal for detecting hotspots, leakages, intrusions, or general condition monitoring over vast areas.

OFSCN provides specialized fiber optic cables, such as the OFSCN® Seamless Steel Tube Fiber Cable, which can serve as the sensing medium for such distributed systems, compatible with Raman, Rayleigh, or Brillouin scattering-based interrogators.

Here are some standard image links for the OFSCN® Seamless Steel Tube Fiber Cable:

For high-precision point sensing (e.g., precise temperature or strain measurements on motor bearings, structural points, or specific machinery components), Fiber Bragg Grating (FBG) sensors are generally more suitable. FBG sensors are discrete, highly accurate, and offer excellent resolution at specific, predefined locations. They allow for multiplexing multiple sensors on a single fiber, providing reliable data from critical points without electromagnetic interference. This method excels when you need very specific data from a limited number of crucial measurement points.

For applications like motor bearings, an OFSCN® Fiber Bragg Grating Temperature Sensor would be a fitting solution. For general strain monitoring, options like the OFSCN® Alloy Tube Packaged Fiber Bragg Grating strain sensor or OFSCN® Polymer-encapsulated Fiber Bragg Grating Strain Sensor can be used depending on the environmental conditions.

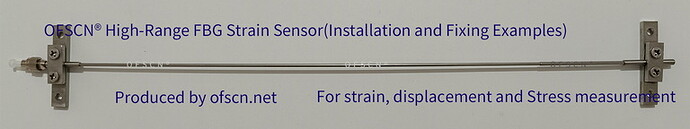

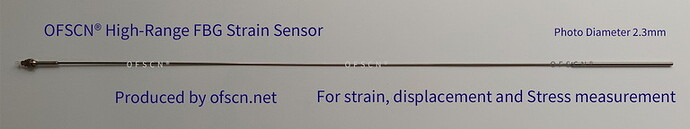

Here are some standard image links for OFSCN® FBG strain sensors:

And for OFSCN® Polymer-encapsulated Fiber Bragg Grating Strain Sensor:

In summary, choose distributed sensing for continuous, wide-area monitoring and FBG sensors for precise, discrete measurements at critical points.