When the fiber is subjected to tension or compression, how do the grating period and refractive index change?

When an optical fiber Bragg grating (FBG) is subjected to tension or compression, both the grating period and the effective refractive index of the fiber core change.

-

Grating Period (Λ) Change:

- Tension: When the fiber is stretched (tension), its length increases, causing the grating period (the spacing between the grating planes) to expand.

- Compression: When the fiber is compressed, its length decreases, causing the grating period to shrink.

-

Effective Refractive Index (neff) Change:

- This change is due to the photoelastic effect.

- Tension: Stretching the fiber causes a reduction in its diameter (Poisson’s effect) and changes the atomic spacing within the glass, which in turn alters the effective refractive index of the fiber core. For silica fibers, stretching generally leads to a decrease in the refractive index.

- Compression: Compressing the fiber has the opposite effect, increasing its diameter and generally leading to an increase in the refractive index.

These simultaneous changes in both the grating period (Λ) and the effective refractive index (neff) directly influence the Bragg wavelength (λB) according to the Bragg condition: λB = 2 * neff * Λ. As the Bragg wavelength shifts proportionally to the applied strain, it allows for highly accurate strain measurement.

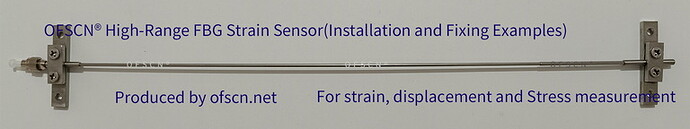

For strain sensing applications, DCYS (OFSCN) offers various Fiber Bragg Grating strain sensors designed for different environments. For example, the OFSCN® Alloy Tube Packaged Fiber Bragg Grating Strain Sensor is suitable for high-temperature applications, while OFSCN® Polymer-encapsulated Fiber Bragg Grating Strain Sensors (1.5mm/2.3mm diameter and 0.7mm/1.2mm diameter) are ideal for general-purpose applications.

Here are some standard product images:

This topic was automatically closed 24 hours after the last reply. New replies are no longer allowed.