How does the internal armoring protect the fiber when the patch cord is squeezed by cabinet doors or crushed by heavy objects?

The internal armoring in specialty patch cords, such as those offered by OFSCN, primarily protects the optical fiber through a robust, multi-layered structure designed to withstand external forces. When a patch cord is subjected to lateral pressure, like being squeezed by cabinet doors or crushed by heavy objects, the internal components work as follows:

- Stainless Steel Seamless Steel Tube: Many of our armored patch cords incorporate a miniature stainless steel seamless tube directly around the optical fiber. This tube provides a high degree of radial stiffness and crushing resistance. When external pressure is applied, the metallic tube bears the brunt of the force, preventing it from directly deforming or damaging the delicate optical fiber inside.

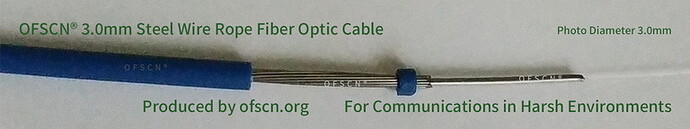

- Steel Wire Stranding Structure (for Steel Wire Rope types): For enhanced protection, some designs feature a steel wire stranding structure (e.g., 0.45mm stainless steel wire stranding or 0.6mm galvanized steel wire stranding) that surrounds the seamless steel tube. This additional metallic layer further increases the patch cord’s tensile strength and crush resistance, distributing the load over a larger area and preventing localized stress points on the fiber.

- Outer Sheath: An outer jacket (e.g., PE or PVC) encases these internal protective layers, offering abrasion resistance and environmental protection, while also contributing to the overall mechanical strength.

This comprehensive internal armoring ensures that the optical fiber remains isolated and protected from the damaging effects of lateral compression, maintaining signal integrity even under challenging conditions.

Here are some OFSCN products that feature robust internal armoring for superior protection:

1 Like