How do coating non-uniformities or lateral pressure cause microscopic wavy bends in the fiber?

Coating non-uniformities and lateral pressure can indeed induce microscopic wavy bends in an optical fiber, leading to micro-bending loss.

Here’s how these mechanisms cause such bends:

-

Coating Non-Uniformities: The polymer coating surrounding an optical fiber provides mechanical protection and acts as a buffer. If this coating has non-uniformities—such as variations in thickness, material properties, or adhesion to the fiber cladding—it creates regions with differing mechanical stiffness or stress concentrations. When the fiber is subjected to external forces (e.g., minor tension, compression, or temperature fluctuations), these non-uniform regions can cause the fiber to buckle or deform into tiny, localized bends instead of experiencing uniform deformation along its length. The weaker or stiffer points in the coating become preferential sites for these micro-bends to form.

-

Lateral Pressure: When an optical fiber experiences pressure applied perpendicular to its axis (lateral pressure), it tries to relieve this compressive stress. If this pressure is unevenly distributed, or if there are inherent imperfections or pre-stresses within the fiber or its coating, the fiber can deform into a series of microscopic wavy bends. This buckling allows the fiber to accommodate the localized compression. These tiny undulations disrupt the smooth path of light.

In both scenarios, these microscopic bends cause a portion of the light propagating within the fiber core to escape into the cladding or radiate out of the fiber altogether. This happens because the local angle of incidence at the core-cladding interface exceeds the critical angle for total internal reflection. This escaped light constitutes the observed optical loss.

To mitigate such effects, OFSCN offers various fiber Bragg grating products with robust designs. For instance, sensors with full metal seamless tube packaging, like the OFSCN® Alloy Tube Packaged Fiber Bragg Grating Strain Sensor, inherently resist micro-bending due to their rigid encapsulation. Even for bare FBGs, the quality of the fiber and its recoating, as seen in products like OFSCN® Polyacrylate Fiber Bragg Gratings / Fiber Bragg Grating Strings (bare), plays a crucial role in maintaining mechanical integrity.

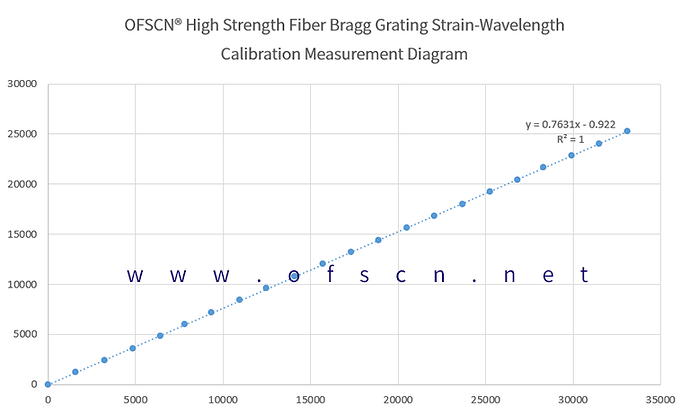

Here is a general illustration of how fiber responds to physical changes:

For more information on our FBG products and their technical specifications, you can visit our website: OFSCN® Polyacrylate Fiber Bragg Gratings / Fiber Bragg Grating Strings (bare).