How can the grating’s perception of strain be amplified through mechanical structures?

Through mechanical structures, the grating’s perception of strain can be amplified by leveraging the mechanical properties of the sensor’s packaging or an external fixture. This involves designing the structure such that a small strain applied to the host material results in a larger, concentrated strain on the optical fiber grating itself.

Common methods include:

- Leverage and Deformation: The packaging can act as a mechanical amplifier, where the deformation of a larger structure is concentrated onto the smaller FBG element. For example, a longer packaging structure or a specific geometric design can translate the external displacement into a magnified strain on the embedded FBG.

- Material Properties: Encapsulating the FBG in materials with specific mechanical properties (e.g., certain plastics or metals) can optimize strain transfer. The packaging material’s stiffness, geometry, and bonding to both the FBG and the host structure play a critical role in how efficiently and linearly the external strain is transferred and potentially amplified.

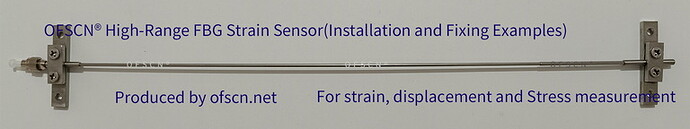

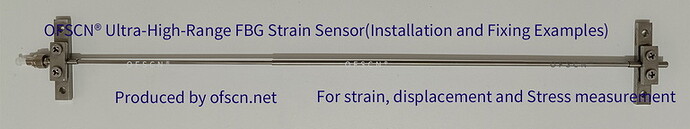

OFSCN offers various packaged Fiber Bragg Grating strain sensors that incorporate such mechanical structures for different application requirements:

-

The OFSCN® Alloy Tube Packaged Fiber Bragg Grating Strain Sensor, for example, uses a full metal seamless tube encapsulation, eliminating creep issues associated with adhesives, making it suitable for long-term high-temperature welding applications where robust strain transfer is crucial.

-

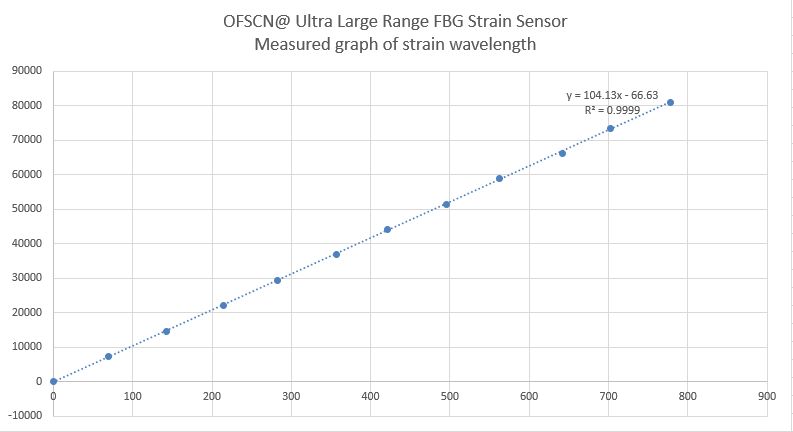

For applications requiring a wider measurement range, the OFSCN® Fiber Bragg Grating Displacement Sensor (which is often based on the OFSCN® Ultra-Large Range Fiber Bragg Grating Strain Sensor) is designed to effectively measure larger displacements by converting them into corresponding FBG strain, demonstrating an amplified response.