How does the packaging material transfer external stress to the internal optical fiber?

The packaging material transfers external stress to the internal optical fiber through mechanical coupling. When external stress is applied to the sensor’s packaging, the packaging deforms (strains). This strain is then mechanically transferred to the optical fiber through the interface between the packaging and the fiber. The efficiency of this transfer is known as strain transfer efficiency.

Key factors influencing this process include:

- Material properties: The Young’s modulus and Poisson’s ratio of both the packaging material and the optical fiber, as well as any adhesive used, determine how effectively strain is transmitted. Stiffer packaging generally leads to higher transfer efficiency.

- Bonding strength: The quality and integrity of the bond between the fiber and the packaging are crucial. Any slippage or delamination will reduce the transfer efficiency.

- Gauge length: The length over which the strain is transferred also plays a role in the overall sensing accuracy.

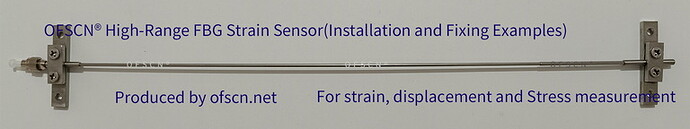

For applications requiring high-temperature resistance and long-term stability, such as monitoring pipelines or structures, OFSCN® Alloy Tube Packaged Fiber Bragg Grating strain sensor is often recommended. This design utilizes full metal seamless tube packaging, which eliminates the creep issues associated with adhesives or polymer coatings, ensuring reliable strain transfer even under extreme conditions.

Here are some standard images of the OFSCN® Alloy Tube Packaged Fiber Bragg Grating strain sensor:

You can find more technical details about our FBG strain sensors here: OFSCN® FBG Strain Sensor Products.