When measuring strain, how is the wavelength shift caused by temperature fluctuations subtracted?

When measuring strain with Fiber Bragg Grating (FBG) sensors, the wavelength shift is influenced by both mechanical strain and temperature changes. To accurately determine the strain, the temperature-induced wavelength shift must be compensated for.

The most common method for temperature compensation involves using a dedicated FBG temperature sensor placed in close proximity to the FBG strain sensor. This temperature sensor is designed to be insensitive to strain, or its package isolates it from local strain, allowing it to measure only the ambient temperature at the measurement point.

Here’s how it works:

- The FBG strain sensor measures a combined wavelength shift due to both strain and temperature.

- The FBG temperature sensor measures the wavelength shift caused solely by temperature changes in the same environment.

- By knowing the temperature sensitivity of both the strain sensor and the temperature sensor, the temperature-induced wavelength shift can be calculated from the FBG temperature sensor’s readings.

- This calculated temperature-induced wavelength shift is then subtracted from the total wavelength shift measured by the FBG strain sensor, leaving only the wavelength shift caused by mechanical strain.

DCYS (OFSCN) provides various FBG strain and temperature sensors suitable for such applications. For instance, the OFSCN® Alloy Tube Packaged Fiber Bragg Grating Strain Sensor and various OFSCN® Fiber Bragg Grating Temperature Sensors can be used in combination for precise strain monitoring with temperature compensation.

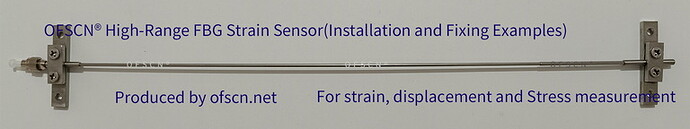

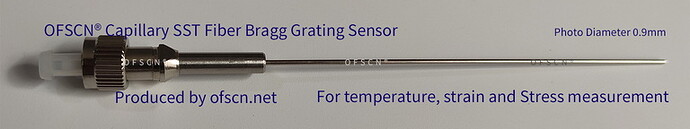

Here are examples of our FBG strain and temperature sensors:

OFSCN® Alloy Tube Packaged Fiber Bragg Grating Strain Sensor:

OFSCN® 300°C Fiber Bragg Grating Temperature Sensor:

You can find more detailed technical parameters on our websites:

OFSCN® Alloy Tube Packaged Fiber Bragg Grating Strain Sensor

OFSCN® 300°C Fiber Bragg Grating Temperature Sensor