Will the packaging structure crack under alternating extreme cold and heat?

OFSCN’s fiber optic sensing products are specifically designed with robust packaging to withstand alternating extreme cold and heat, ensuring the integrity of the packaging structure under thermal cycling conditions. This is achieved through the selection of appropriate materials and sophisticated encapsulation techniques.

For high-temperature applications, we utilize seamless metal tube packaging, which offers excellent resilience against thermal expansion and contraction without cracking. For ultra-low temperature environments, specialized low-temperature resistant polymer materials are employed for encapsulation.

For example, our OFSCN® Alloy Tube Packaged Fiber Bragg Grating Strain Sensor is engineered with full metal seamless tube packaging, allowing it to operate reliably from -200℃ to 300℃.

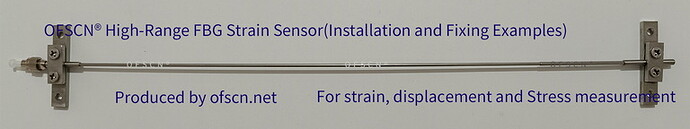

Here are some standard images of our alloy tube packaged sensors:

Similarly, the OFSCN® 300°C Fiber Bragg Grating Temperature Sensor and OFSCN® 500°C Fiber Bragg Grating Temperature Sensor also employ seamless steel tube encapsulation, providing stable operation in ranges from -200℃ to 300℃ and -200℃ to 500℃, respectively. The OFSCN® Ultra-low temperature FBG temperature sensor uses low-temperature resistant polymer packaging, suitable for temperatures from -270℃ to 150℃.