How many millions of cycles of reciprocal vibration can the sensor withstand?

The number of cycles a Fiber Bragg Grating (FBG) sensor can withstand under reciprocal vibration is highly dependent on various factors, including the amplitude and frequency of the vibration, the strain range, temperature, environmental conditions, and the specific design and packaging of the sensor. A bare optical fiber, even with an FBG, can experience fatigue over time, especially under high strain amplitudes or in abrasive environments.

To enhance durability and fatigue life under cyclic loading, OFSCN® offers specialized solutions:

-

OFSCN® High-Strength Fiber Bragg Gratings / Fiber Bragg Grating Strings (Bare): These utilize high-strength polyimide-coated optical fibers, designed to withstand larger strain ranges (≥25000με) and a wider temperature range (-200℃ to 300℃). This inherent design improves their resistance to fatigue compared to standard acrylate-coated fibers.

You can find more details here: OFSCN® High-Strength Fiber Bragg Gratings / Fiber Bragg Grating Strings (Bare) -

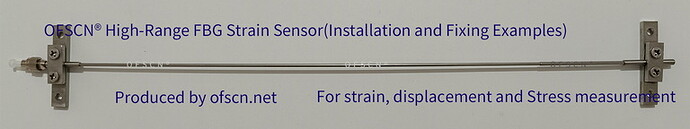

OFSCN® Alloy Tube Packaged Fiber Bragg Grating Strain Sensor: For applications requiring greater robustness and protection against mechanical stress, abrasion, and harsh environments, we recommend our packaged FBG sensors. The OFSCN® Alloy Tube Packaged Fiber Bragg Grating strain sensor employs a full metal seamless tube encapsulation. This packaging significantly isolates the optical fiber from direct external forces, preventing creep from adhesives and enhancing its mechanical stability and fatigue resistance, making it ideal for long-term monitoring under demanding conditions such as high temperatures or welding installations.

Here are some standard product images for the OFSCN® Alloy Tube Packaged FBG Strain Sensor: