How is it transformed into kilometers of thin optical fiber via a drawing tower?

The transformation of a fiber preform into kilometers of thin optical fiber is achieved through a specialized process involving a fiber drawing tower.

Here’s a simplified explanation:

- Preform Feeding: The high-purity glass preform (a large, cylindrical rod, typically a few centimeters in diameter and a meter or so in length) is slowly fed into the top of the drawing tower.

- Heating: The tip of the preform enters a high-temperature furnace, which heats the glass to its softening point (around 1900-2200°C).

- Drawing: As the glass softens, gravity and a precisely controlled pulling mechanism at the base of the tower draw a thin strand of molten glass downwards. This strand rapidly thins out to the diameter of an optical fiber (typically 125 microns for the glass cladding).

- Diameter Control: Laser micrometers continuously monitor the fiber’s diameter, and feedback systems adjust the drawing speed and furnace temperature to maintain a consistent, precise diameter.

- Coating: Immediately after drawing and while still hot, the bare glass fiber passes through one or more applicators that apply a protective polymer coating. This coating is crucial for protecting the fragile glass from abrasion and environmental factors. UV light or heat then cures these coatings.

- Cooling and Winding: The coated fiber is then cooled and carefully wound onto a large spool, ready for further processing or cabling.

This continuous process allows for the production of several kilometers of optical fiber from a single preform.

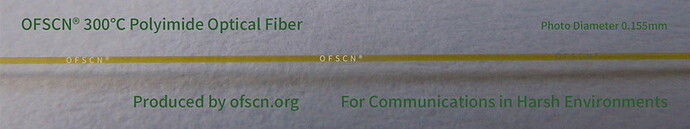

OFSCN leverages advanced drawing technology to produce a wide range of specialized optical fibers. For example, we offer: