To what extent can a steel-tube-packaged sensor be bent without damaging the internal optical fiber?

The “Minimum Bending Radius” of a steel-tube-packaged sensor, often referred to as Fiber In Metal Tube (FIMT) or similar constructions, is a critical technical parameter primarily determined by several factors:

- Optical Fiber Characteristics: The internal optical fiber itself has a bending tolerance. Exceeding this can lead to macro-bending loss, which attenuates the optical signal, or, in severe cases, cause the fiber to fracture.

- Metal Tube Characteristics: The most significant limiting factor is the metallic packaging. The material, outer diameter, and wall thickness of the seamless steel tube dictate its flexibility. The tube must not undergo permanent deformation, such as kinking or flattening, as this would inevitably damage the optical fiber inside.

- Product Design: The specific design of the packaged sensor, including how the fiber is integrated within the tube and any buffering layers, also plays a role in its overall bendability.

Therefore, the exact minimum bending radius is product-specific and should always be referenced in the technical datasheet of the particular OFSCN® product.

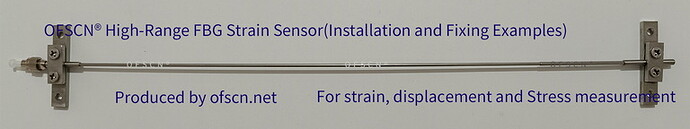

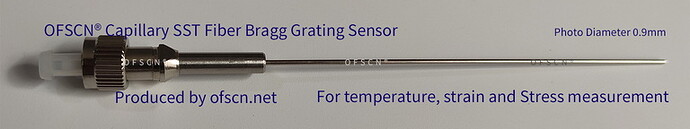

OFSCN offers several products utilizing metal tube packaging for enhanced durability and performance, such as the OFSCN Alloy Tube Packaged Fiber Bragg Grating Strain Sensor, the OFSCN® 300°C Fiber Bragg Grating Temperature Sensor, and the OFSCN® 500°C Fiber Bragg Grating Temperature Sensor.

Here are some standard product images for these types of sensors:

For further details, you can consult the relevant product pages on our website.