Many manufacturers claim 300°C but only for short-term use. What is the material matching logic behind OFSCN’s long-term reliability?

For long-term stability at 300°C, OFSCN® sensors primarily rely on all-metal seamless encapsulation technology. Many conventional sensors, even those rated for 300°C, often use organic adhesives or polymer coatings which can degrade, creep, or outgas over extended periods at high temperatures, leading to signal drift or sensor failure.

OFSCN® addresses this by encapsulating the Fiber Bragg Grating (FBG) within a seamless alloy tube. This material matching logic offers several advantages:

- Elimination of Organic Materials: By using an all-metal structure, the issues associated with high-temperature degradation of organic glues or polymer coatings are eliminated.

- Mechanical Protection: The metal encapsulation provides robust mechanical protection, enhancing the sensor’s durability in harsh environments.

- Stable Thermal Expansion: The metallic structure is engineered for stable thermal expansion, minimizing thermal-induced stress on the FBG itself and ensuring consistent performance over a wide temperature range.

This design ensures that the sensor can operate reliably for extended durations at 300°C without significant drift or degradation.

One example of a product utilizing this technology is the OFSCN® 300°C Fiber Bragg Grating Temperature Sensor, which typically employs single-layer seamless steel tube encapsulation.

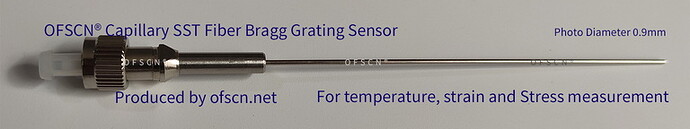

Here are some standard product images illustrating the design:

For strain sensing in similar conditions, the OFSCN® Alloy Tube Packaged Fiber Bragg Grating Strain Sensor also leverages an all-metal encapsulation for high-temperature applications.

You can find more detailed technical parameters on our websites:

OFSCN® 300°C Fiber Bragg Grating Temperature Sensor

OFSCN® Alloy Tube Packaged Fiber Bragg Grating Strain Sensor

OFSCN® OFDR Micro All-Metal Strain Sensor (depending on the internal fiber, can reach 300°C)