Many sensors require plastic hoses for protection. Why can OFSCN’s stainless steel housing directly contact the medium?

OFSCN® sensors, particularly those with stainless steel housing, are designed for direct contact with the medium due to their robust encapsulation technology, which eliminates the need for additional external sheathing like plastic hoses.

The primary reasons are:

- Seamless Metal Encapsulation: OFSCN® sensors often utilize seamless steel tube encapsulation (e.g., stainless steel, alloy). This design provides inherent mechanical protection against physical damage, corrosion, and pressure, making them suitable for harsh environments.

- High-Temperature Resistance: Unlike plastic hoses which degrade at elevated temperatures, the metal encapsulation allows the sensors to withstand high temperatures (e.g., up to 300°C or even higher for specialized versions) without compromising performance or integrity.

- Elimination of Creep and Degradation: For strain sensors, traditional adhesive-based encapsulation or plastic sheathing can suffer from creep over time, especially at varying temperatures, leading to measurement inaccuracies. The direct metal encapsulation of OFSCN® sensors eliminates these issues, ensuring long-term stability and accuracy.

- Chemical Resistance: The choice of stainless steel or other alloys provides superior resistance to various chemical mediums that would typically degrade plastic protections.

For instance, the OFSCN® Alloy Tube Packaged Fiber Bragg Grating Strain Sensor and the OFSCN® 300°C Fiber Bragg Grating Temperature Sensor are examples that leverage this technology for applications requiring direct contact in demanding environments.

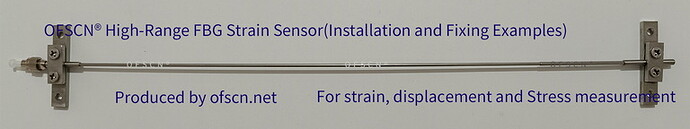

Here are some standard images illustrating the robust design:

1 Like