In MRI environments, why must non-magnetic packaging materials be selected?

In MRI environments, non-magnetic packaging materials are crucial because the strong magnetic fields used in Magnetic Resonance Imaging would interact with any ferromagnetic or paramagnetic materials. This interaction can lead to:

- Image Artifacts: Magnetic materials distort the magnetic field homogeneity, creating distortions or dark spots in the MRI images, making diagnosis difficult or impossible.

- Safety Hazards: Ferromagnetic materials can become dangerous projectiles under the influence of the strong magnetic field, posing a risk to patients and staff.

- Heating: Magnetic materials can heat up due to induced eddy currents in rapidly changing magnetic fields, potentially causing burns.

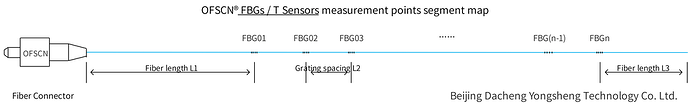

OFSCN® Fiber Bragg Grating (FBG) sensors are inherently immune to electromagnetic interference (EMI) because they are entirely dielectric. This makes them ideal for use in high electromagnetic field environments like MRI, as the sensing principle itself is unaffected by magnetic fields. However, for any FBG sensor system deployed in an MRI scanner, its packaging and any other associated components must still be constructed from non-magnetic materials to ensure MRI compatibility, prevent image interference, and maintain safety.

You can find more technical details about our FBG sensors, including their EMI immunity, on our website:

OFSCN® Fiber Bragg Grating Strain Sensor