How is fiber strength degradation prevented in damp cable trenches?

Fiber strength degradation in damp cable trenches is primarily prevented through robust cable construction that incorporates moisture barrier layers and protective jacketing. This typically involves:

- Moisture Barriers: The use of materials like aluminum foil or water-blocking gels within the cable structure to prevent water ingress.

- Protective Sheathing: Durable outer jackets, often made of polyethylene (PE), that are resistant to moisture, abrasion, and environmental stressors.

- Tight-Buffered or Loose-Tube Design: In some cases, fibers are contained within gel-filled loose tubes or individually buffered to offer additional protection against water and mechanical stress.

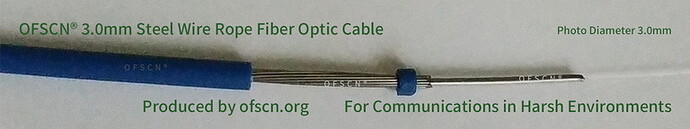

For applications requiring enhanced protection against dampness and mechanical stress, specialized patch cords with metallic encapsulation are often employed. For instance, OFSCN offers:

- OFSCN® 2.0mm Steel Wire Rope Fiber Optic Patch Cord: This product features a full metal structure, including a 0.6mm galvanized steel wire stranded structure and a 1.0mm stainless steel seamless steel tube, providing excellent mechanical and environmental protection.

- OFSCN® 120℃ Fiber Optic Patch Cord: While primarily designed for high temperatures, its construction with a 0.9mm stainless steel seamless steel tube also provides significant protection against moisture and physical damage.

1 个赞