Why does using temperature sensors as level gauges require extremely high longitudinal positioning accuracy?

The OFSCN® Fiber Bragg Grating Liquid Level Sensor operates by utilizing a series of precisely positioned Fiber Bragg Grating (FBG) temperature sensors along a “reference scale.” The system identifies the liquid level by detecting a significant temperature difference between the liquid below the surface and the gas above it, as sensed by these individual FBG points.

Therefore, extremely high longitudinal positioning accuracy is crucial because:

- Direct Level Mapping: Each FBG sensing point corresponds to a specific, known vertical position. The system determines the liquid level by identifying which FBG points are submerged (experiencing liquid temperature) and which are above the surface (experiencing gas temperature). Any inaccuracy in the longitudinal placement of these FBG points directly translates into an error in the reported liquid level.

- Spatial Resolution: The accuracy of the liquid level measurement is inherently linked to the spatial resolution, which is the distance between consecutive FBG sensing points. Precise positioning ensures that this intended resolution is maintained and that the transitions detected by the FBGs accurately reflect the actual liquid-gas interface.

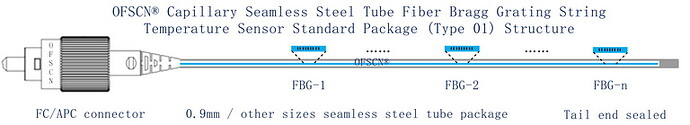

Here is a standard image of the sensor’s application:

You can find more details on our website: OFSCN® Fiber Bragg Grating Liquid Level Sensor.