Why can multi-point FBG temperature sensors be used as a “ruler” to precisely locate liquid levels?

Multi-point FBG temperature sensors can be used as a “ruler” for precise liquid level localization because they leverage the principle of differential temperature measurement.

Here’s how it works:

When a multi-point FBG temperature sensor string is submerged in a liquid, and there’s a significant temperature difference between the liquid below the surface and the gas (or another fluid) above the surface, each FBG along the string will register a different temperature depending on whether it’s in the liquid or the gas.

By monitoring the temperature readings from each FBG, a distinct temperature boundary can be identified along the sensor string. This boundary corresponds precisely to the liquid level. Since each FBG is at a known, fixed position along the fiber, the system effectively uses these individual temperature measurement points as discrete markers on a “ruler” to pinpoint the liquid level’s exact height.

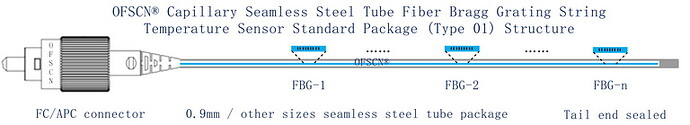

For this application, we recommend the OFSCN® Fiber Bragg Grating Liquid Level Sensor, which is based on the technology of the OFSCN® 300°C Fiber Bragg Grating Temperature Sensor.

Here are some standard images of the product: