Why do organic coatings fail in ultra-high temperature environments (above 500°C)? How does metal coating protect the silica core?

Organic coatings, such as polyacrylate or polyimide, fail in ultra-high temperature environments (above 500°C) primarily due to thermal decomposition. At elevated temperatures, the organic molecules break down, leading to the loss of the coating’s structural integrity. This results in embrittlement, charring, and eventual delamination, which can degrade the optical fiber’s mechanical properties and expose the silica core to environmental factors. For instance, polyacrylate coatings typically have a maximum operating temperature of around 100°C, and polyimide coatings can withstand up to 300°C.

Metal coatings, like gold, protect the silica core through several mechanisms:

- High-Temperature Stability: Gold has a high melting point and does not decompose at temperatures above 500°C, making it suitable for extreme temperature applications (up to 700°C for OFSCN gold-coated fibers).

- Hermetic Sealing: The metal coating creates a hermetic seal around the silica core, preventing the ingress of moisture and other corrosive gases. This is crucial as moisture can lead to static fatigue and long-term degradation of the fiber’s strength.

- Enhanced Mechanical Protection: Metal coatings provide superior mechanical protection compared to organic coatings, making the fiber more robust against abrasion and micro-bending losses.

For environments above 500°C, we recommend using OFSCN® Gold-coated Optical Fiber.

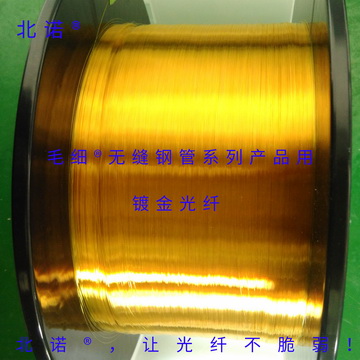

Here are some standard images of our gold-coated optical fiber:

You can find more detailed parameters at: https://www.ofscn.org/optical-fibers/gold-coated.html