What are the fundamental differences in principle and application between LPGs and short-period FBGs?

The fundamental differences between Long Period Gratings (LPGs) and short-period Fiber Bragg Gratings (FBGs) lie in their grating period, light coupling mechanism, and consequently, their primary applications.

Principle Differences:

-

Grating Period:

- FBGs (Short-Period): Have a very short grating period, typically in the range of hundreds of nanometers (e.g., ~0.5 µm). This short period is comparable to half the guided wavelength in the fiber, which enables coupling between forward-propagating and backward-propagating core modes.

- LPGs (Long-Period): Possess a much longer grating period, typically in the range of hundreds of micrometers (e.g., 100 µm to 1000 µm). This long period facilitates resonant coupling between the forward-propagating core mode and various forward-propagating cladding modes.

-

Light Coupling Mechanism:

- FBGs: Act as a wavelength-selective mirror. They reflect a narrow band of wavelengths that satisfy the Bragg condition (λ_Bragg = 2 * n_eff * Λ, where n_eff is the effective refractive index of the core mode and Λ is the grating period) while transmitting all other wavelengths.

- LPGs: Do not reflect light. Instead, they cause discrete wavelengths from the core mode to couple into co-propagating cladding modes. These cladding modes are typically lossy (due to interaction with the fiber coating or external environment) and radiate away from the fiber, resulting in distinct attenuation bands (dips) in the transmission spectrum.

Application Differences:

-

Sensitivity and Measurands:

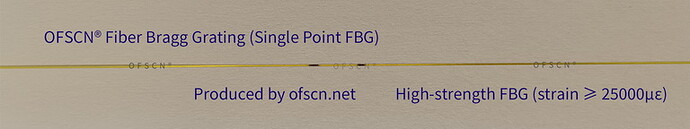

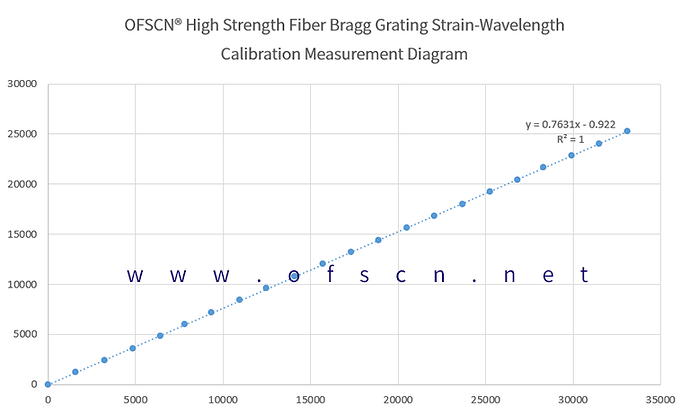

- FBGs: Are primarily sensitive to changes in strain and temperature, which alter the effective refractive index of the core and the grating period, thus shifting the Bragg wavelength. They are ideal for high-precision, localized point sensing of these parameters. For example, OFSCN® FBG Strain Gauges are used for structural health monitoring.

- LPGs: Are highly sensitive to changes in the external refractive index (ERI) of the surrounding medium, as well as temperature and curvature. Their strong dependence on ERI makes them excellent candidates for chemical, biological, and environmental sensing applications.

-

Spectral Response:

- FBGs: Exhibit a sharp, narrow reflection peak (and a corresponding transmission dip) at the Bragg wavelength. This makes them well-suited for wavelength-division multiplexing (WDM) for multi-point sensing along a single fiber.

- LPGs: Show broad attenuation bands in their transmission spectrum. While sensitive, their broad spectral features can make multiplexing multiple LPGs more challenging compared to FBGs.

-

Environmental Robustness:

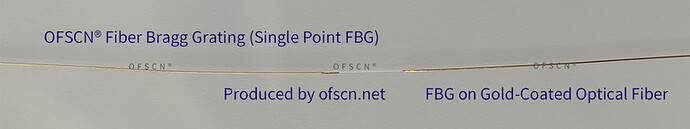

- Both FBG and LPG sensors can be designed for various environments. For instance, bare FBGs like the OFSCN® Polyacrylate Fiber Bragg Gratings can operate from -40℃ to 100℃, while specialized OFSCN® Gold-Coated Fiber Bragg Gratings can extend the temperature range up to 700℃. The robust packaging of FBG sensors, such as the OFSCN® Alloy Tube Packaged Fiber Bragg Grating Strain Sensor, further enhances their durability in harsh industrial settings.

In summary, FBGs are excellent for precise strain and temperature measurements, often in multiplexed arrays, by monitoring wavelength shifts in reflection. LPGs, on the other hand, are more suited for refractive index sensing and specific temperature or curvature applications, by observing changes in their broadband transmission dips.

Here are some standard image links for OFSCN’s FBG products:

This topic was automatically closed 24 hours after the last reply. New replies are no longer allowed.