How are fiber optic connectors protected in offshore wind power applications?

In offshore wind power applications, fiber optic connectors require robust protection due to exposure to harsh conditions such as salt spray, high humidity, extreme temperatures, and mechanical stress. Effective protection strategies typically involve:

- Industrial-Grade Connectors: Utilizing connectors specifically designed for harsh environments, often featuring corrosion-resistant materials (e.g., stainless steel), and sealed designs to prevent moisture and contaminant ingress.

- Sealing Mechanisms: Employing gaskets, O-rings, and sometimes potting or encapsulation to create hermetic seals around the connector interface and cable entry points.

- Robust Cable Assemblies: Integrating connectors with highly durable and armored fiber optic cables, which provide significant mechanical protection, strain relief, and contribute to the overall integrity of the optical link.

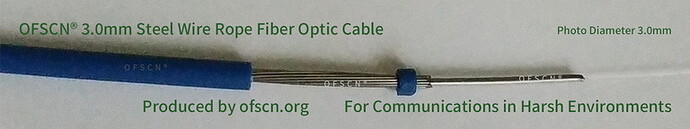

Our OFSCN® Seamless Steel Tube Fiber Cables and OFSCN® 3.0mm Steel Wire Rope Fiber Optic Patch Cords are designed to provide exceptional durability and protection for the optical fiber itself in challenging environments, including those prone to corrosion and mechanical stress. These robust cabling solutions are a foundational element in ensuring the long-term reliability of fiber optic links, supporting the integrity of connections.

Here are examples of our robust cabling solutions:

1 个赞